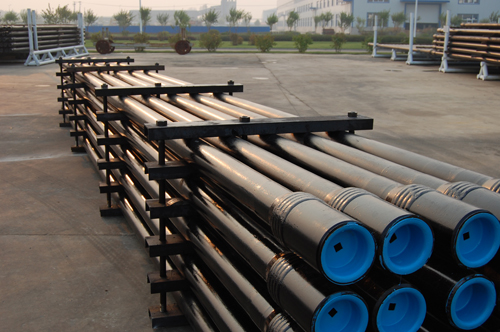

产品展示

从2 3/8″到6 5/8″不同规格的API标准钻杆严格按照美国石油协会 Spec 5DP和RP 7G的标准加工制造。也可以根据用户在特定条件下的个性需要,设计和制造特殊用途的石油钻杆。

Drill pipes from 2 3/8” to 6 5/8” are manufactured strictly conform to the requirements of API Spec 5DP and RP 7G. At the same time, PDM can design and manufacture special drilling tools required by customers.

管体原材料的优选 Optimized Selection of Raw Materials

钻杆管体采用符合美国钢铁协会(AISI)要求的高性能特种合金钢。除了初次采购的严格筛选和审查,所有原材料在进厂之后,都将按照API要求进行相应的化学成份、金相组织和几何尺寸的检测。管体热处理之后,公司还将对调质后的管体进行机械性能和化学成份分析,并采用水浸式超声波探伤设备进行全长无损检测。

The drill pipe is made of low carbon alloy steel according to AISI specifications. After the strict screening and auditing of the green pipe manufacturers, all the raw materials will be inspected by PDM for chemical composition analysis, metallographic structure and physical dimension according to the requirements of API Spec 5DP. After heat treatment, the pipe’s mechanical properties are tested, and metallographic analysis and American OEM magnetic flux leakage inspections are applied.

钻杆接头的加工 Manufacturing of Tool Joints

钻杆接头选用AISI4137或AISI4140优质合金钢制造。热处理采用日本预抽真空加热炉、计算机控制淬火和回火热处理工艺,机械性能高、均匀性好。生产过程中对每一个接头产品进行荧光磁粉和超声波探伤检测,确保产品质量,可以跟据用户需要在钻杆接头外表上敷焊美国ARNCO 100XT 、300XT等耐磨带。

Tool joints are made of AISI 4137 or AISI 4140 low carbon alloy steel. For heat treatment, our equipment is imported from Japan. Cybernation quenching and tempering are applied which can obtain mechanical properties and metallographical homogeneity expected. Wet magnetic particle and ultrasonic testing will be carried out to every tool joint during manufacturing to ensure the quality. American ARNCO 100XT or 300XT hardband can be chosen by customers for their tool joints.