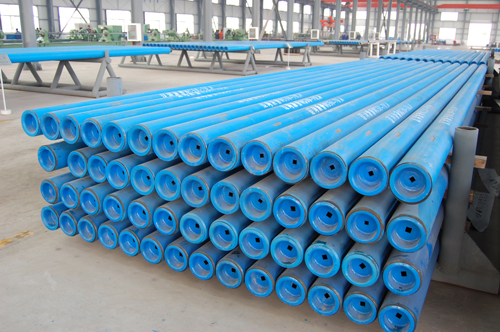

产品展示

公司可以提供外径范围从3 1/8〞到11〞、长度范围从5英尺到31英尺的各种长度的钻铤产品,包括普通钻铤、螺旋钻铤以及带有应力释放结构、卡瓦槽、吊卡槽等特殊加工要求的钻铤产品。

PDM provides slick or spiral drill collars with the outer diameter from 3 1/8” to 11” and with the length from 5 feet to 31 feet. Slip or elevator grooves, stress relief features (SRF), cool rolled process for SRF or roots of connections, and other requirements can be made by customers.

原材料的优选 Raw Material for Drill Collars

采用符合AISI标准要求的AISI 4137、4145H或4145HM合金钢,此类钢在冶炼过程中能有效地控制硫、磷等微量元素的含量,使得材料能够获得很高的物理性能。除了原材料进厂之后进行的化学成分、金相组织等常规检测,热处理前后两次的全长水浸超声波无损探伤,更是将因原材料缺陷带来的使用风险规避到最小。

Alloy steel of AISI 4137, 4145H or 4145HM are adopted to manufacture drill collars. In the smelting process of raw material, the content of sulfur, phosphorus and other harmful elements are effectively controlled, which guarantees appropriate physical properties. Beside general inspections such as chemical composition and metallographic structure for raw material ,before and after heat treatment, with full length CNC ultrasonic tested for two times, PDM dedicates to reduce user’s drilling risks caused by the original flaw in raw materials to the least.

热处理工艺 Heat Treating Process

钻铤热处理采用先进的中频感应加热方式进行淬火和回火。利用计算机控制技术对工艺参数进行精确控制,对热处理过程中的每一个阶段进行实时的严格监控。与大专院校合作,优化钻铤的热处理工艺,加大了检测力度,对每支钻铤两端全部进行理化性能检测,从而保证了产品的整体质量。

Advanced line-frequency induction heating method is applied in quenching and tempering for drill collars. CNC technology is applied in monitoring and recording every process of heat treatment. PDM cooperates with advanced R&D institutes or collages for heat treatment and inspection technology. To monitor the quality stability of all the products, PDM samples every drill collar product from two ends to mechanical properties.

螺旋槽的加工 Groove Machining for Spiral Drill Collars

公司可以根据用户要求提供防止差动压力阻滞的螺旋钻铤。此类钻铤可以减少其与井壁的接触表面积,有效地降低产生差动压力阻滞的可能性,利于岩屑顺利排出,有效地避免了粘扣的发生。公司与专业院校合作研制了大型数控螺旋铣床加工螺旋槽,提高生产效率的同时,有效地保证了切削深度的均匀性及外观质量,避免截面突变和应力集中。

PDM supplies spiral drill collars which can effectively reduce the danger of differential pressure sticking particularly in deviated or horizontal holes. Spiral drill collars can reduce the contact surface between the out surface of drill collars and the inner wall of the hole, and establish a better hydraulic characteristic for drilling mud, therefore avoid jamming of drilling debris. Cooperate with professional colleges, PDM has developed CNC spiral milling machine to manufacture spiral grooves, which effectively improves the uniformity of the cutting depth and efficiency of production line.

应力释放结构的加工 Stress Release Features

为了提高钻具产品的疲劳寿命,应用户要求,可以提供符合API Spec 7-1的规定加工应力释放结构。

In order to improve the fatigue life of drilling products, if customer requests, PDM can machine stress release features specified in API Spec 7-1.

辅助加工 Assist Processing

螺纹根部残余应力的释放对于减少螺纹的疲劳非常有效。公司自主开发了专用设备,对螺纹根部进行冷滚压处理,并对螺纹进行镀铜、磷化处理,避免钻具螺纹的粘扣现象。

The release of residual stress in the thread root is very effective to reduce the drilling tool fatigue. Cold rolling process for the roots of threads can be made with the equipment developed by PDM. Copper coating or thread parkerizing reduces the galling frequency of drilling tools, and customer can choose either of them.